We would like to provide you with some guidance on what you should pay attention to when purchasing your filling / bottling machine. We will address the topics of design, materials and durability.

The design and the materials to be used in machinery are specified by regulations and standards at both the EU level and additionally on the national level.

The Machinery Directive (2006/42/EC) is the most important directive concerning the construction of machinery. Other EU regulations govern the use of materials and articles intended to come into contact with food. Examples include Regulation (EU) No. 10/2011 and (EC) No. 1935/2004. EU directives and regulations establish specific safety standards and health requirements for products, including machinery and electrical appliances. The CE marking is used by the manufacturer to demonstrate that they are aware of the relevant requirements for their product and that their product complies with these rules. Products lacking the CE marking are not allowed to be distributed within the EU.

Having provided an overview of the relevant regulations and standards, we would now like to shed light on the associated design aspects.

This will allow you to make a preliminary assessment of the offered quality before purchasing a filling machine.

These requirements have been met in the design and construction of our FILLOGY® filling machines as follows:

FILLOGY® filling devices are consistently designed so that all parts and surfaces are smooth, quick, and easy to clean. All machine components that come into contact with the product and are used in the filling of food items are demonstrably approved for food use.

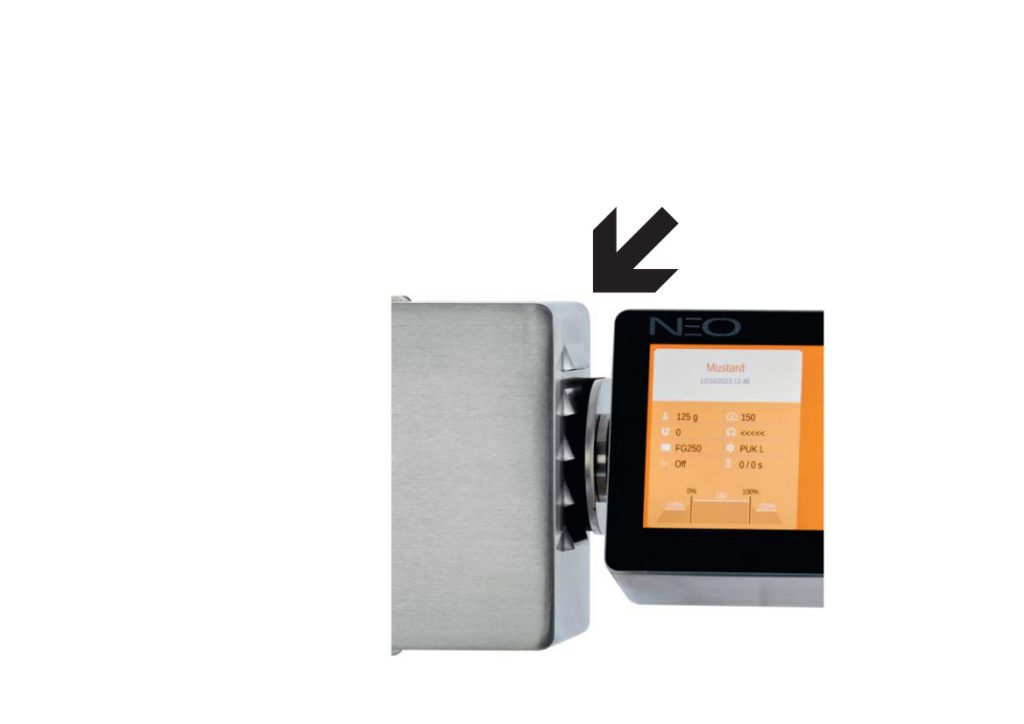

Example illustration of the FILLOGY® Neo motor block: The surfaces are smooth and easy to clean. There are no gaps or indentations where product or cleaning residues could accumulate.

Example illustration of a filling machine, which, in contrast, has larger gaps in the splash area. In these hard-to-clean areas, contaminants can accumulate over time, leading to persistent residue.

When selecting a filling machine, the materials used play a crucial role. They not only influence the performance and durability of the machine but also have implications for product safety, hygiene, and regulatory compliance.

Product Safety:

The materials from which a filling machine is made can come into contact with the filled products. Therefore, it is crucial to choose materials that do not release harmful substances or could contaminate the product. Especially in the food and pharmaceutical industries, the materials must be food-safe and non-hazardous.

Corrosion Resistance:

Filling machines often come into contact with liquids or chemicals. The chosen materials should be resistant to corrosion to ensure a long machine lifespan and minimize the need for frequent repairs or replacements.

Hygiene Requirements:

In industries like food, beverages, and pharmacy, strict hygiene standards are a necessity. The materials should be easy to clean to prevent the accumulation of dirt, germs, and bacteria. Smooth, non-porous, and easily accessible surface design facilitates cleaning.

Robustness and Wear Resistance:

The bottling machine is subject to daily use and mechanical stress. High-quality materials contribute to the robustness and wear resistance of the machine, ensuring its performance over time.

Temperature and Chemical Resistance:

Depending on the type of products being filled, the machines can come into contact with various temperatures and chemicals. The materials used must withstand these conditions without compromising their structure or properties.

Compatibility with Cleaning Agents:

For the regular cleaning of the filling machine, cleaning agents and disinfectants are often used. The materials must be compatible with these chemicals to avoid causing damage or reducing cleaning efficiency.

Compliance with Standards:

Certain industries have specific material requirements. Ensure that the materials used adhere to the relevant industry standards and regulations, such as FDA approval for the food industry.

The durability of a filling machine is not just a technical attribute but a crucial factor that influences the overall performance and profitability of a production facility. By investing in a durable filling machine, you ensure that your company benefits from stable and efficient production in the long term.

We provide you with fast and straightforward maintenance and repair services for your machine. Additionally, you can count on us for quick replacement of accessories and wear parts. We focus on quality.

Further Informationen can be found here.

© 2019-2024 FILLING EVOLUTION GmbH. All rights reserved.